What Are Industrial Brakes, And How Are They Useful?

What do you think about when you hear braking systems? It may be cars or trucks; however, industrial brakes are used in heavy equipment like backhoes, construction excavators, or skid steers.

You can also find spring set brakes on medical imaging equipment, processing equipment, etc. It’s important to understand the components of these industrial brakes to be easy when installing them for your machinery.

What’s the Purpose of the Industrial Braking System?

Industrial brakes serve the purpose of decelerating or bringing to a halt the motion of machinery or components. They accomplish this by utilizing friction to dissipate the kinetic energy generated during movement. Other brakes vary in function and the mechanism they use to impede mechanical motion.

Here are examples of industrial brakes components

- Holding brakes: this braking system keeps a machine stopped until it’s released.

- Dynamic brakes: these brakes apply friction to a running machine to a complete stop as the load rotates.

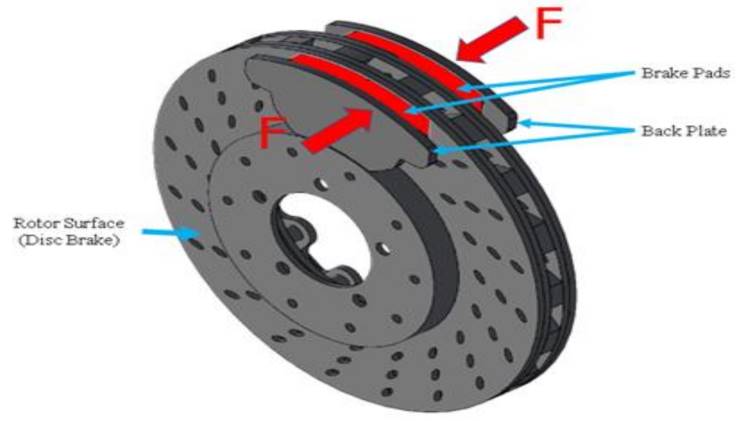

Various brakes, such as holding, dynamic, or a combination of both, are crucial n for different equipment or components. Drum brakes and disc brakes belong to the category of dynamic brakes. Disc brakes are suitable for situations requiring high torque, provided sufficient room can accommodate the brakes.

Conversely, drum brakes are utilized for lower torque applications and may be constrained by space limitations. To operate, drum brakes may rely on a pneumatic release, electro hydraulic thruster, a hydraulic release, or an electromagnetic solenoid.

Industrial Braking Systems Types

The industrial can also be broken into further parts like

Spring-loaded brakes: Spring-applied brakes are commonly used to slow down moving loads or keep static loads in place when the release mechanism is deactivated. These brakes rely on electromagnetic solenoids to disengage and are particularly valuable for applications such as overhead cranes, winches, general industrial machines, and emergency stops.

Hydraulic release brake: This is a type of spring-set drum brake using hydraulic power for movable braking torque. This type of brake is most useful for winch holding, stage productions, and emergency stops.

Hydraulic release brakes are spring-applied drum brakes that utilize hydraulic power to adjust the braking torque. These brakes are particularly useful for winch holding, stage productions, and emergency stops.

Failsafe brakes: Fail-safe brakes are designed to stop motion in case of power loss or issues with the PLC or variable frequency drive. These brakes are mostly used in elevators, conveyor belt systems, crane hoists, oil and mining winches, steel mill coiling and rolling systems, drawbridges, and.

Way to Maintain Industrial Brakes

Every part of the machine needs good maintenance, including the industrial brakes. Let’s check how to maintain them

- Adjustment: Ensure the brakes are adjusted correctly to prevent slippage or insufficient braking force.

- Level installation: if you level your machine, things will run more smoothly so as its breaks

- Testing: Test the brakes periodically to ensure they work correctly and can stop the load in an emergency.

- Cleaning: Clean the brake components regularly to remove any dust, dirt, or debris that can cause damage to the brakes.

- Replacement: Replace any worn or damaged brake components immediately to prevent brake failure.

- Change oil: Braking systems that rely on hydraulic actuation require regular hydraulic oil cleaning. These oils can become contaminated with dust, grit, condensed water, and heat, leading to expensive repairs and downtime. To prevent this, changing the oil, filters, and regularly checking the oil levels is essential. By doing so, you can help ensure the braking system’s reliability and prevent costly repairs and downtime.

- Load regulation: When a machine is overfilled, or its loads are unevenly distributed, it can strain the equipment excessively. This can result in uneven wear on the brakes or even complete brake failure.

- Follow manufacturer’s instructions: always Follow the manufacturer’s instructions for the maintenance, repair, and replacement of brake components.

Conclusion

To ensure that the braking system does not adversely affect downstream mechanisms, it is crucial to have a comprehensive understanding of equipment system design. Opting for a supplier who delivers high-quality breaks and offers maintenance and replacement parts enables you to develop design strategies that align with your operational requirements. Moreover, you can gain a competitive edge in your industry by upgrading your components using spring set brake systems to match the expansion of your operations, resulting in efficient and adaptable processes.